The Powerhouse of Precision: Understanding the Heavy Duty Saw Machine

In the industrial world, where materials like steel, massive timber, and high-density composites are routinely processed, a standard tool simply won't suffice. This is the domain of the heavy duty saw machine, a specialized category of equipment engineered for unrelenting power, supreme durability, and uncompromised precision in the most demanding cutting applications.

These industrial behemoths are the backbone of numerous sectors, from structural steel fabrication and aerospace manufacturing to large-scale woodworking and specialized metal service centers. Their core purpose is to tackle materials that are too thick, too hard, or too numerous for conventional cutting tools, ensuring speed, accuracy, and efficiency on a grand scale.

Key Types of Heavy Duty Saw Machines

The term "heavy duty saw machine" encompasses several different designs, each optimized for specific tasks and materials:

-

Horizontal Bandsaws: Perhaps the most common type for industrial metal cutting, these machines use a continuous loop of toothed blade that travels horizontally as it cuts down through a stationary workpiece. Their robust construction and often automated feeding systems make them ideal for high-volume, straight-line cutting of bar stock, pipes, and beams. For extreme size and stability, double-column bandsaws are the choice for cutting massive blocks and slabs.

-

Vertical Bandsaws: While smaller vertical models are used for intricate contour cutting, the heavy-duty versions are crucial for slicing large plates and blocks, particularly in metal fabrication and tool-making. The operator moves the material against a static, vertically oriented blade, offering greater flexibility for shaping.

-

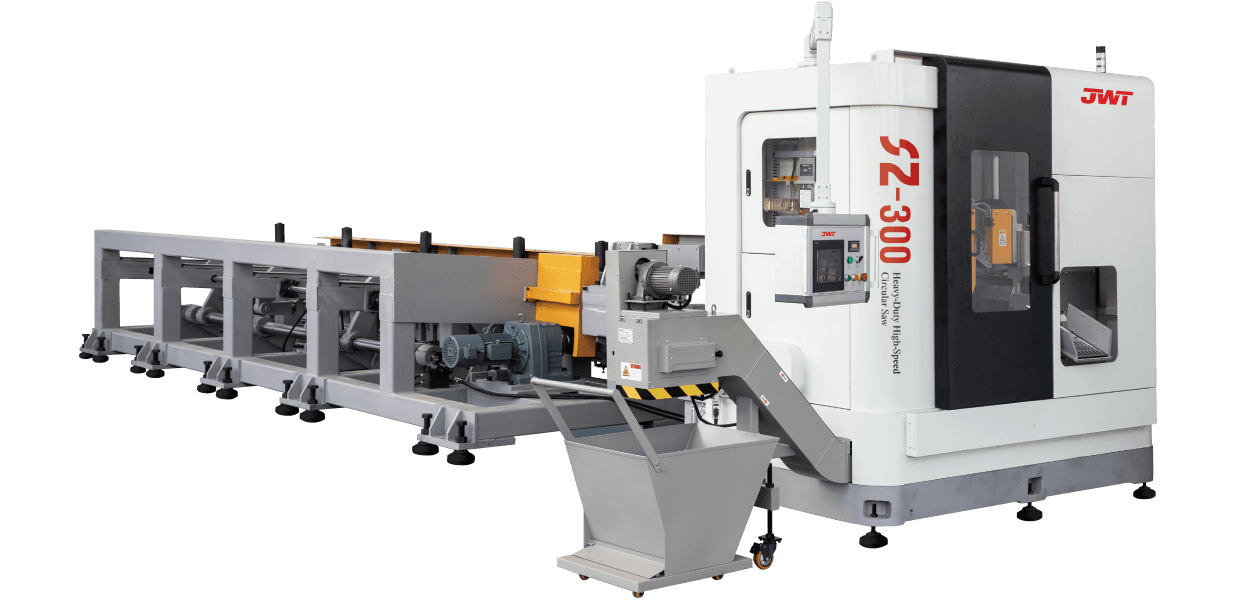

Cold Saws (Circular Saws): These employ a circular, toothed blade designed for minimal heat distortion, providing clean, virtually burr-free cuts on metal. Heavy-duty cold saws are engineered for rapid, high-precision straight and angled cuts on profiles, tubes, and solid bars. Their mechanical stability is key to achieving the smooth, finished edges required in many industries.

-

Abrasive/Friction Saws: When the material is exceptionally hard or tough, such as high-alloy steel, friction or abrasive saws use a high-speed rotating wheel (either abrasive or a dull-toothed disc) to essentially melt or grind through the workpiece. While the cut finish may be rougher, the cutting speed on difficult materials can be unmatched.

Essential Features for Heavy Duty Performance

What sets a dedicated heavy duty saw machine apart are the features that ensure consistent performance under load:

-

Rigid Construction: A stable, heavy machine base—often cast iron or a thick-welded steel frame—is crucial. This mass absorbs vibration and deflection, which is vital for maintaining blade alignment and cut accuracy when sawing through dense materials.

-

High-Powered Motors and Drive Systems: Industrial-grade saw machines feature powerful motors (often with variable speed drives) to maintain high torque and blade speed even when encountering resistance, preventing stalls and ensuring a clean cut.

-

Advanced Cooling and Lubrication: Cutting metal generates immense heat. Heavy-duty models incorporate recirculating coolant systems that continuously flood the cutting zone. This not only cools the blade and workpiece but also flushes away chips, extending blade life and maintaining material integrity.

-

Automation and Control: Many top-tier heavy-duty saws are semi- or fully-automatic, featuring CNC (Computer Numerical Control) systems. These allow for precise programming of cut lengths, angles (mitering), and batch sizes, dramatically increasing throughput and repeatability.

-

Robust Workholding: Powerful, often hydraulic, clamping systems are mandatory to securely hold large, heavy workpieces. This prevents movement during the cut, which is essential for both accuracy and operator safety.

Applications Across Industries

The versatility of the heavy duty saw machine makes it indispensable in numerous industrial settings:

-

Structural Steel: Cutting massive H-beams, I-beams, and columns for bridges, buildings, and other large structures.

-

Automotive & Aerospace: Precision cutting of metal stock, specialized alloys, and extruded profiles used in component manufacturing.

-

Foundries and Forgings: Trimming risers and gates from cast or forged components.

-

Tool and Die Making: Precisely slicing large blocks of tool steel to size before final machining.

Choosing the right heavy duty saw machine is a critical investment that directly impacts a company's production capacity and product quality. For any operation focused on high-volume, high-precision processing of challenging materials, these industrial power tools are the only solution capable of reliably meeting the heavy demands of modern manufacturing.

中文简体

中文简体 русский

русский