Revolutionizing Fabrication: The Power of the High Speed Saw Machine

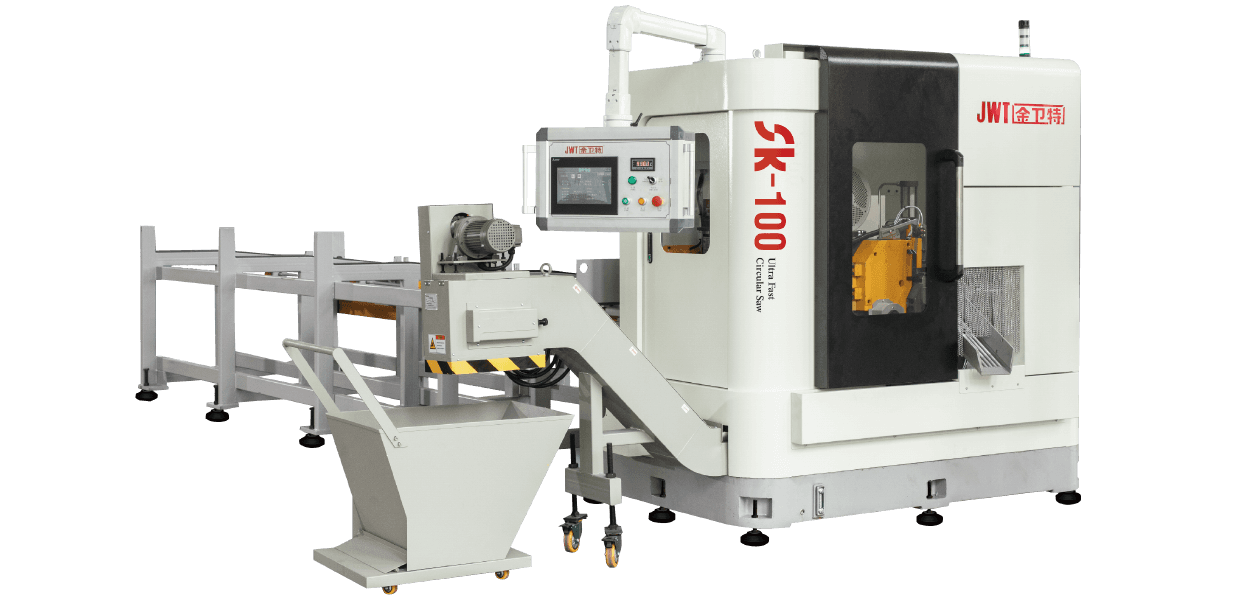

The High Speed Saw Machine stands as a pivotal piece of equipment in modern metalworking, fabrication, and manufacturing industries. Designed for unparalleled efficiency and precision, these machines are indispensable for cutting a wide range of materials, including various metals, alloys, and occasionally other dense materials, at significantly faster rates than traditional sawing methods. Their speed and accuracy make them a crucial investment for operations aiming to maximize throughput and minimize material waste.

Key Features and Technology

What sets the High Speed Saw Machine apart is its optimized combination of power, blade technology, and control systems.

1. Superior Blade Velocity

The most defining characteristic is the machine's ability to drive the saw blade at extremely high surface speeds. This velocity is crucial for achieving a clean, rapid cut, particularly in materials that are heat-sensitive or prone to work hardening. The increased speed translates directly into reduced cycle times for each cut, boosting overall production capacity.

2. Advanced Blade Composition

To withstand the rigors of high-speed operation, the blades used in a High Speed Saw Machine are typically made from highly durable materials, such as High-Speed Steel (HSS), Tungsten Carbide-tipped (TCT), or specialized ceramic composites. The geometry and tooth configuration of these blades are precision-engineered for specific material types, ensuring optimal chip removal and minimal burr formation.

3. Precision Control Systems

Modern High Speed Saw Machines are often integrated with advanced CNC (Computer Numerical Control) systems. These controls allow for precise programming of cutting parameters, including material feed rate, cut length, and blade speed. This level of automation ensures repeatable accuracy, tight tolerances, and efficient use of raw stock, which is critical in high-volume production environments.

Applications Across Industries

The versatility of the High Speed Saw Machine makes it a cornerstone in several key sectors:

-

Metal Fabrication: Cutting structural steel, tubing, and profiles for construction and general fabrication projects.

-

Automotive Industry: Precision-cutting components for engine parts, chassis, and exhaust systems.

-

Aerospace: Working with specialized, high-strength alloys where precision and material integrity are paramount.

-

Pipe and Tube Manufacturing: Providing fast, clean cuts on continuous production lines.

The ability of the High Speed Saw Machine to deliver a smooth finish often reduces or eliminates the need for secondary operations like deburring or grinding, providing a significant time and cost advantage.

Choosing the Right Machine

When selecting a High Speed Saw Machine, manufacturers consider several factors:

-

Material Type and Size: The machine must be rated for the specific type of metal (e.g., ferrous or non-ferrous) and the maximum dimensions of the stock being cut.

-

Required Output: The machine's speed and automation level should match the required daily or weekly production volume.

-

Accuracy and Tolerance: For applications demanding extremely tight specifications, a machine with superior rigidity and advanced feedback control is necessary.

In summary, the continuous evolution of the High Speed Saw Machine solidifies its role as an essential tool in modern manufacturing. By delivering a blend of speed, precision, and efficiency, it continues to drive productivity and quality across global industries.

中文简体

中文简体 русский

русский