The Precision and Power of the Automatic Saw Machine

The modern manufacturing landscape demands speed, accuracy, and efficiency, and few tools embody these requirements as perfectly as the Automatic Saw Machine. This sophisticated piece of industrial equipment has revolutionized how materials like wood, metal, plastic, and composites are cut, moving beyond the limitations of manual and semi-automatic operations to deliver unparalleled precision and throughput.

Defining the Automatic Saw Machine

An Automatic Saw Machine is an industrial tool designed to execute cutting operations with minimal human intervention. Unlike traditional saws that require an operator to manually position the material, initiate the cut, and manage the feed rate, the automatic version handles the entire process autonomously, following pre-set programming. This automation typically encompasses material loading, clamping, cutting sequence execution, and even material offloading or sorting.

Key Components and Operation

The complexity and function of an Automatic Saw Machine are derived from the integration of several key components:

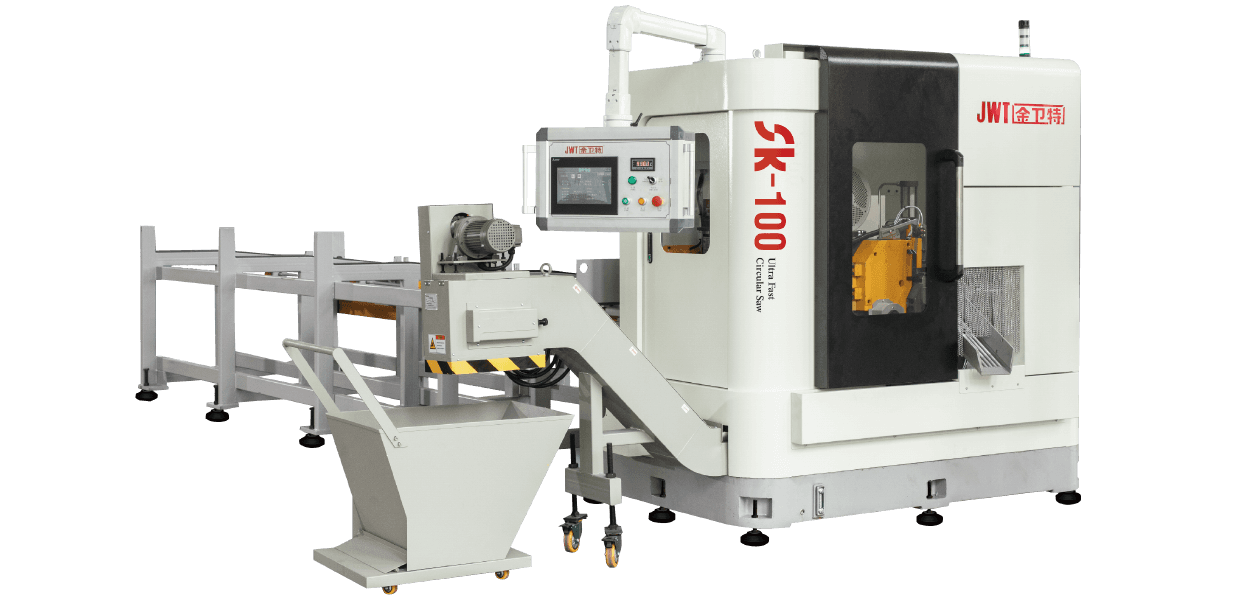

- Cutting Head: This houses the saw blade (e.g., circular, band, or abrasive disc) and the motor that drives it. The type of blade dictates the material the machine can effectively process.

- Material Feed System: This is often a conveyor, gripper, or shuttle vise that precisely moves the raw material into the cutting area. Accuracy here is paramount for ensuring consistent cut lengths.

- Clamping Mechanism: Hydraulic, pneumatic, or electric clamps secure the material firmly during the cut to prevent movement, which is critical for safety and dimensional accuracy.

- Control System (PLC/CNC): The Programmable Logic Controller (PLC) or Computer Numerical Control (CNC) unit is the brain of the Automatic Saw Machine. Operators use this interface to program cut lengths, angles, quantities, and operational speed.

- Safety Features: Modern machines include safety interlocks, protective guarding, and emergency stops to ensure operator well-being.

The operation begins when the material is loaded. The CNC program then takes over, directing the feed system to position the material. Clamps engage, the cutting head advances at a programmed speed and rate, and the precise cut is made. The cycle repeats based on the quantity programmed, often executing hundreds or thousands of cuts per shift with minimal deviation.

Applications Across Industries

The versatility of the Automatic Saw Machine makes it indispensable across numerous sectors:

- Metalworking: Used to batch-cut stock materials (bars, tubes, profiles) for fabrication shops, automotive components, and structural steel construction. High-speed, high-precision band saws and circular cold saws dominate this field.

- Woodworking: Essential in furniture making, lumber mills, and construction for rapidly and accurately sizing planks, panels, and intricate joinery components.

- Plastics and Composites: Critical for industries like aerospace and marine manufacturing where high-quality, clean cuts on demanding materials are required.

- Electronics: Precision Automatic Saw Machines are used for dicing and singulating printed circuit boards (PCBs) and substrates.

Advantages Over Traditional Methods

The shift to an Automatic Saw Machine offers significant operational benefits compared to manual or semi-automatic alternatives:

| Feature | Automatic Saw Machine Advantage |

|---|---|

| Precision | 0.1 mm or better. Consistent, repeatable cuts eliminate human error and waste. |

| Efficiency | Runs continuously, often unsupervised for large batches, dramatically increasing production throughput. |

| Safety | Operator is removed from the immediate cutting area, reducing exposure to moving parts and flying debris. |

| Material Yield | Sophisticated software can “nest” or optimize cut lists to minimize scrap material. |

中文简体

中文简体 русский

русский