Efficiency and Precision: A Comprehensive Guide to High-Speed Circular Saw Machines

Understanding the Mechanics of High-Speed Circular Saw Machines

High-speed circular saw machines are engineered for industrial environments that demand rapid, high-volume cutting with extreme accuracy. Unlike standard saws, these machines utilize advanced spindle technology and high-torque motors to drive specialized blades—such as TCT (Tungsten Carbide Tipped) or Cermet—at velocities often exceeding 3,000 to 5,000 RPM. This high velocity ensures that the blade spends less time in contact with the material per cut, which significantly reduces heat buildup and prevents thermal deformation of the workpiece.

The structural integrity of these machines is built around a heavy-duty, torsion-free frame. This robust construction is essential to dampen the vibrations generated by high-speed rotation. When vibrations are minimized, the machine can achieve a "mirror-level" surface finish, often eliminating the need for secondary grinding or deburring processes. This makes them a staple in automotive, aerospace, and heavy fabrication industries where tolerance levels are tight.

Core Features and Technical Specifications

Advanced Automation and CNC Integration

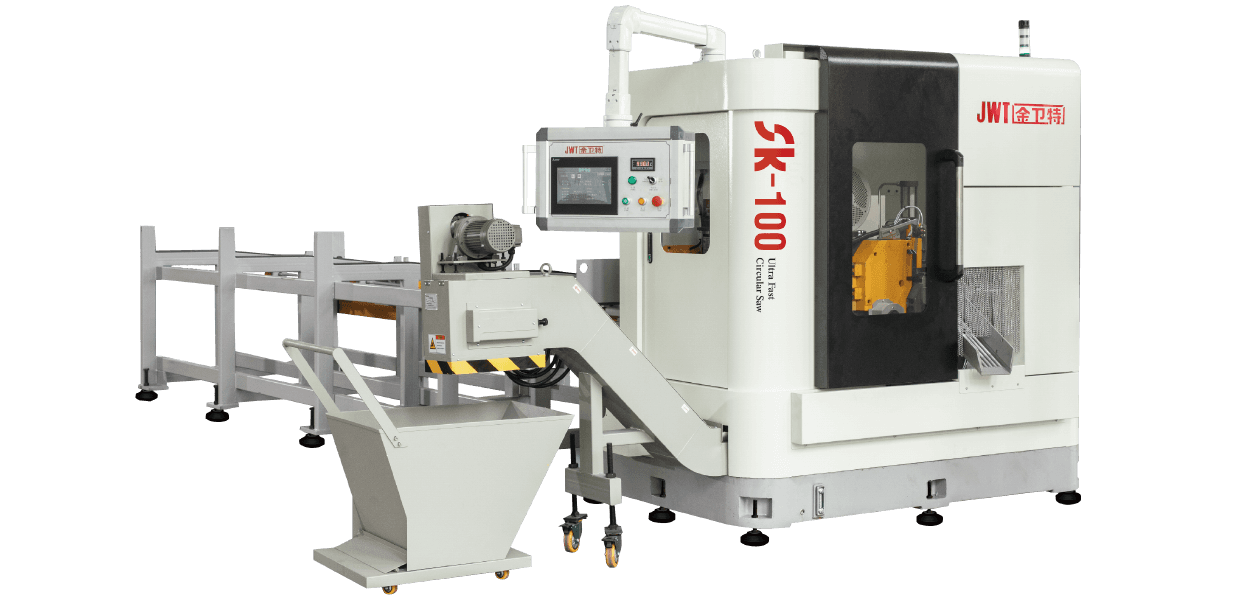

Modern high-speed circular saws are frequently equipped with CNC (Computer Numerical Control) systems. This allows operators to program precise cutting lengths, feed rates, and quantities through a user-friendly HMI (Human-Machine Interface) touchscreen. Automated features often include:

- Auto-loading magazines for continuous bar feeding.

- Servo-driven ball screws for precise material indexing and head movement.

- Automatic trim-cut and remnant sorting to minimize material waste.

Cooling and Lubrication Systems

To maintain blade longevity at high speeds, these machines incorporate micro-mist or flood cooling systems. This targeted lubrication reduces friction between the teeth and the metal, extending blade life by up to 25%. Advanced models may even feature multi-fluid cooling concepts designed specifically for difficult-to-cut alloys like Inconel or stainless steel.

Comparative Performance: Materials and Speeds

The versatility of a high-speed circular saw machine depends largely on its ability to adapt to different material densities. The table below outlines typical operating parameters for industrial applications:

| Material Type | RPM Range | Typical Application |

| Ferrous Metals (Steel) | 20 - 150 RPM | Solid bars, heavy pipes |

| Non-Ferrous (Aluminum) | 2000 - 5500 RPM | Extrusions, sheets |

| Wood and Plastics | 3000 - 6000 RPM | Construction panels |

Maintenance Protocols for Peak Efficiency

Regular maintenance is critical to prevent downtime and ensure the safety of the operator. Because these machines operate at such high velocities, even minor misalignments or debris buildup can lead to blade failure or motor strain. A disciplined maintenance schedule should include daily cleaning of the saw blade and chip conveyor to prevent metal shards from clogging the internal mechanics.

Lubrication of the linear guide ways and ball screws should be performed according to the manufacturer's cycle—often weekly or monthly depending on shift volume. Furthermore, blade inspection is paramount; operators must look for signs of dulling or tooth chips. Replacing a blade early is far more cost-effective than allowing a dull blade to increase the load on the spindle motor, which could result in a costly 70% increase in equipment failure risk over time.

Safety Features and Industry Standards

Safety in high-speed sawing cannot be overstated. Modern machines are designed with fully enclosed cutting areas to protect workers from high-speed chips and accidental contact. Integrated sensors detect blade deflection in real-time; if the blade begins to bend or vibrate excessively, the system triggers an emergency stop to prevent a catastrophic break. Additionally, electronic brakes are standard, ensuring the blade stops rotating within seconds of the cycle ending or an emergency button being pressed.

中文简体

中文简体 русский

русский