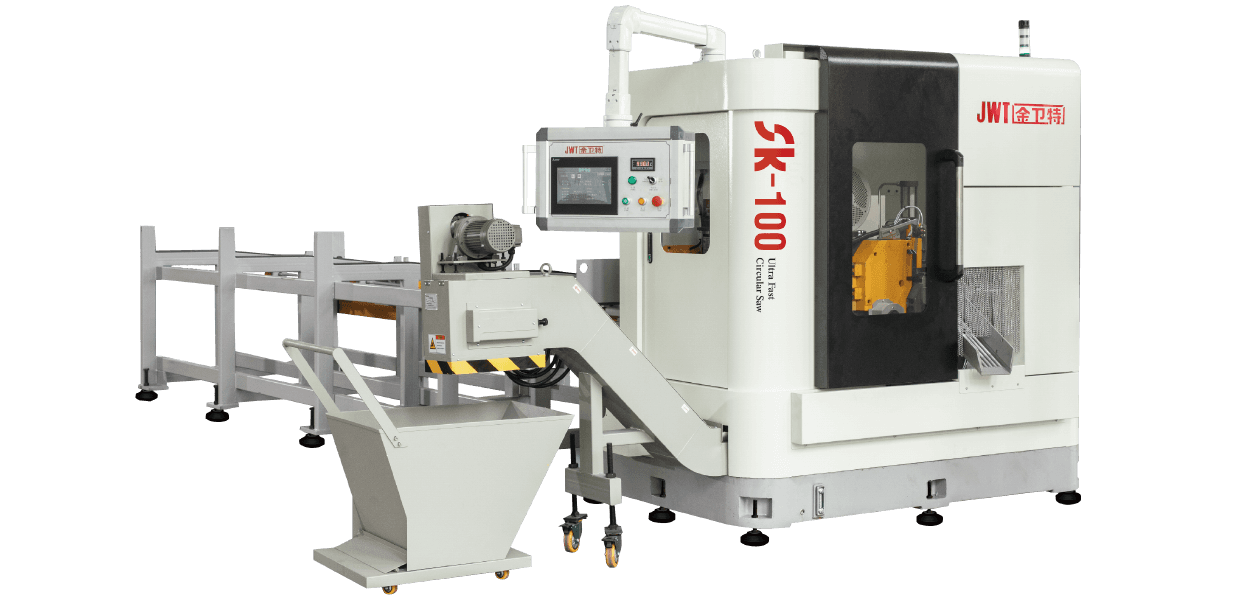

Unlocking Productivity: How High-Speed Circular Saw Machine Tools Are Redefining Industrial Cutting Standards

When it comes to industrial cutting applications, few tools rival the sheer efficiency and reliability of high-speed circular saw machine tools. These powerful machines are redefining what’s possible in terms of speed, precision, and adaptability, making them a cornerstone of modern fabrication processes.

A New Era of Speed and Precision

At the heart of any high-speed circular saw’s success is its ability to operate at unprecedented speeds without compromising accuracy. Traditional saws often struggle to balance speed with quality, leading to rough edges or uneven cuts. However, high-speed variants leverage advanced engineering principles to overcome these limitations.

For instance, many high-speed circular saws utilize direct-drive motors that eliminate unnecessary mechanical components, resulting in smoother operation and reduced vibration. This translates into cleaner cuts, especially when working with delicate or thin materials. Furthermore, variable speed controls enable operators to fine-tune the machine based on the task at hand, whether it’s slicing through thick steel plates or trimming lightweight aluminum profiles.

Versatility Without Compromise

One of the most compelling aspects of high-speed circular saw machine tools is their adaptability. From heavy-duty industrial environments to smaller workshops, these machines cater to a wide range of applications. For example:

Metal Fabrication : High-speed saws are invaluable in cutting tubing, angles, and flat bars with exceptional precision. Their ability to handle ferrous and non-ferrous metals alike makes them indispensable in fabrication shops.

Plastics and Composites : When working with materials prone to melting or chipping, such as acrylics or fiberglass, the controlled speed and cooling systems of these saws prevent damage while maintaining dimensional accuracy.

Construction : On-site cutting of structural steel and piping becomes faster and safer with portable high-speed circular saws, which offer mobility without sacrificing performance.

Smart Features Enhance Usability

Modern high-speed circular saws are more than just robust cutting machines—they’re smart devices designed to streamline workflows. Many models boast integrated software that allows users to save custom cutting programs, track blade wear, and monitor operational metrics in real time. Such functionality not only boosts productivity but also empowers operators to make data-driven decisions.

Safety has also been prioritized in recent designs. Features like automatic shut-off systems, blade guards, and emergency stop buttons ensure that workers remain protected even when operating at high speeds. Additionally, noise reduction technologies minimize auditory strain, creating a more comfortable work environment.

Cost-Effectiveness Through Longevity

While the initial investment in a high-speed circular saw machine tool may be higher than conventional alternatives, the long-term savings are undeniable. Thanks to their durable construction and low-maintenance design, these machines boast longer lifespans. Reduced blade wear, lower energy consumption, and decreased material waste all contribute to a healthier bottom line.

Moreover, the elimination of secondary processing steps—such as deburring or grinding—frees up resources that can be redirected toward other critical tasks. This holistic approach to cost management underscores why so many businesses are making the switch to high-speed circular saws.

中文简体

中文简体 русский

русский