Revolutionizing Precision Cutting: The Rise of High-Speed Circular Saw Machine Tools

In today’s fast-paced manufacturing landscape, precision and efficiency are paramount. Industries ranging from automotive to aerospace demand tools that can deliver high-quality cuts with minimal waste and maximum speed. Enter the high-speed circular saw machine tool—a game-changer in the world of metalworking and woodworking alike.

What Sets High-Speed Circular Saws Apart?

High-speed circular saws have emerged as a premier choice for industrial cutting due to their ability to handle tough materials with remarkable accuracy. Unlike traditional saws, these machines operate at significantly higher RPMs (revolutions per minute), enabling them to slice through metals, plastics, and composites with ease. This increased speed not only reduces cycle times but also enhances the smoothness of the cut, minimizing burrs and imperfections.

One standout feature is their advanced blade technology. Modern high-speed circular saw blades are crafted from premium materials like carbide or diamond-tipped alloys, which ensure durability and longevity. Coupled with precise blade geometry, these tools can maintain sharpness over extended periods, reducing downtime for blade changes and maintenance.

Benefits Across Industries

The versatility of high-speed circular saw machine tools makes them indispensable across various sectors. In the automotive industry, they’re used for cutting structural components, exhaust systems, and chassis parts. Their ability to produce clean, burr-free edges eliminates secondary finishing processes, saving both time and labor costs.

Similarly, in construction and infrastructure projects, these machines excel at slicing through steel beams, pipes, and rebar. With adjustable feed rates and programmable settings, operators can tailor the machine to specific material requirements, ensuring optimal performance every time.

Woodworking professionals also benefit from high-speed circular saws when working on intricate designs or large-scale production runs. The precision offered by these tools ensures consistent results, even when dealing with hardwoods or engineered wood products.

Technological Advancements Driving Innovation

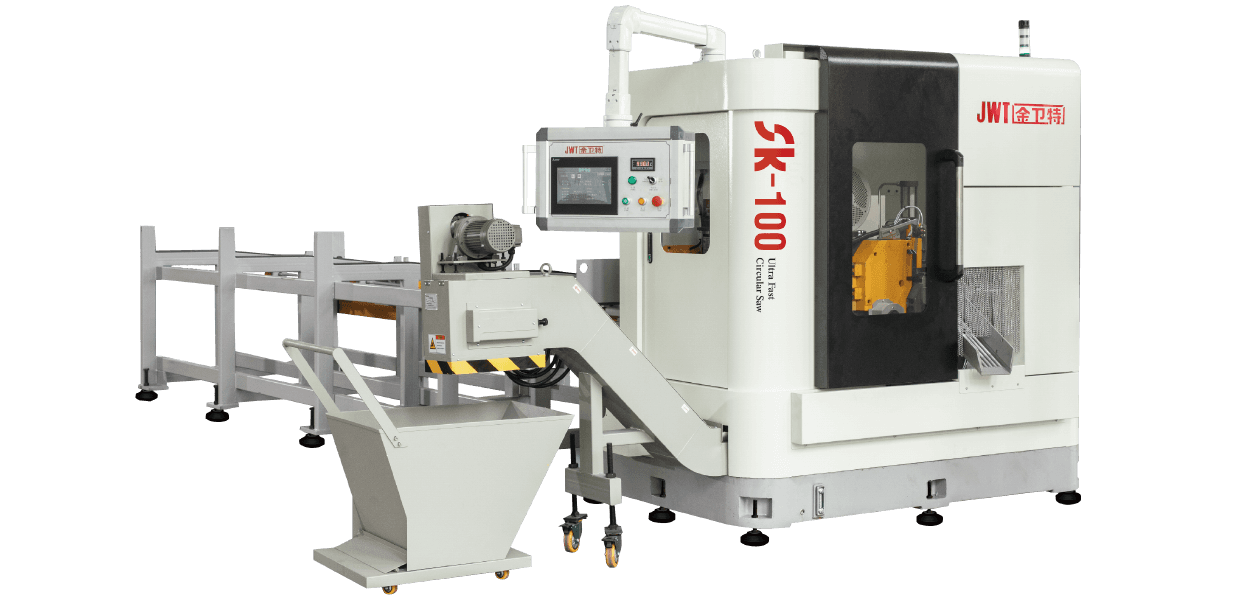

Recent advancements in automation and CNC (Computer Numerical Control) integration have further elevated the capabilities of high-speed circular saws. Many models now come equipped with touch-screen interfaces, real-time monitoring systems, and automatic feed mechanisms. These features allow for seamless operation, reducing human error and increasing productivity.

Additionally, some high-end models incorporate laser-guided alignment systems, ensuring pinpoint accuracy during setup. This innovation is particularly beneficial for industries where tolerances are tight and margins for error are slim.

Sustainability Meets Efficiency

Another advantage of high-speed circular saw machine tools lies in their sustainability. By optimizing cutting parameters and reducing material wastage, these machines contribute to greener manufacturing practices. Moreover, their energy-efficient motors consume less power compared to older technologies, aligning with global efforts to reduce carbon footprints.

As manufacturers continue to prioritize eco-friendly solutions, high-speed circular saws represent an ideal blend of performance and environmental responsibility.

中文简体

中文简体 русский

русский