Industrial circular saw machine applications

Industrial circular saw machines are indispensable tools in modern manufacturing, known for their efficiency, precision, and versatility. These powerful machines are designed to meet the rigorous demands of industrial-scale cutting, processing a wide range of materials with speed and accuracy. Unlike handheld saws, industrial models are stationary, heavy-duty pieces of equipment that are essential for high-volume production in various sectors.

Key Applications Across Industries

The applications of the industrial circular saw machine are diverse and critical to many industries. In the metalworking industry, these machines are used to cut steel, aluminum, brass, and other alloys into precise shapes and sizes for components like pipes, rods, and structural beams. Their ability to deliver clean, burr-free cuts is crucial for subsequent processes like welding and machining.

For the woodworking and construction industries, the industrial circular saw machine is a workhorse. It is used to quickly and accurately cut large sheets of plywood, lumber, and composite materials for everything from furniture manufacturing to the creation of building components. The precision of these machines ensures minimal material waste and consistent quality.

In the plastics and composites sector, these saws are vital for cutting materials like acrylic, polycarbonate, and fiberglass. They are engineered to prevent melting or chipping, which is a common problem with less specialized tools. This precision is essential for producing high-quality parts for automotive, aerospace, and medical applications.

The Technology Behind the Precision

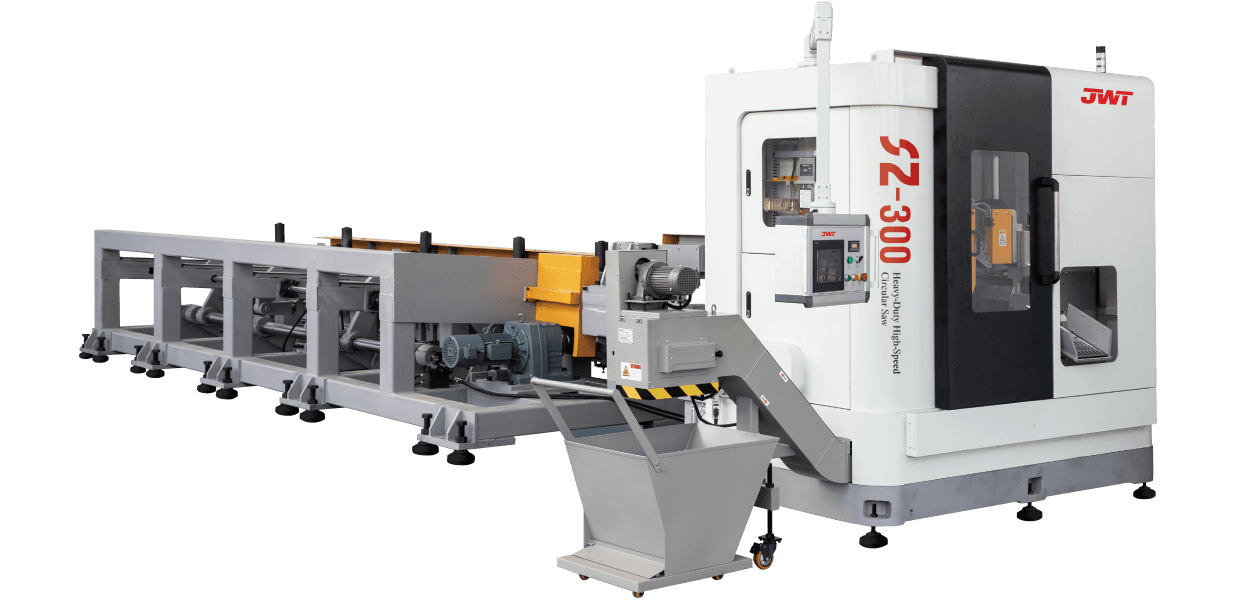

The effectiveness of an industrial circular saw machine comes from its robust design and advanced features. These machines typically include powerful motors, hardened steel blades, and advanced control systems. Many modern models are equipped with automated feeding systems and programmable logic controllers (PLCs), allowing for complex and repetitive cuts with minimal human intervention. This automation not only increases efficiency but also significantly enhances operator safety.

Furthermore, safety features are paramount. Guarding systems, emergency stop buttons, and dust collection ports are standard, protecting workers and ensuring a clean working environment. The durability and reliability of these machines mean they can operate continuously under heavy loads, making them a cornerstone of industrial productivity.

Ultimately, the industrial circular saw machine is more than just a cutting tool; it is a fundamental component of the manufacturing ecosystem. Its precision and power enable industries to produce high-quality goods at scale, driving innovation and efficiency across global supply chains.

中文简体

中文简体 русский

русский